LED patch light-emitting diodes are one of the most common devices in semiconductor equipment. Most semiconductors are made of doped semiconductor materials (atoms and other substances). The conductor materials of LED patch light-emitting diodes are usually aluminum arsenide. In pure aluminum arsenide, all atoms are perfectly combined with their neighbors, leaving no free electrons to connect to the current. In doped substances, additional atoms change the electrical balance, either by increasing free electrons or creating holes through which electrons can pass. Both of these additional conditions make the material more conductive. A semiconductor with extra electrons is called an N-type semiconductor. Because it has extra negatively charged particles, in an N-type semiconductor material, free electrons flow from the negatively charged area to the positively charged area. Bring extra

The "electron hole" semiconductor is called a P-type semiconductor, because it contains positively charged particles. Electrons can jump from another electron hole to another electron hole, and flow from a negatively charged region to a positively charged region. Therefore, the electron holes themselves appear to flow from the positively charged region to the negatively charged region.

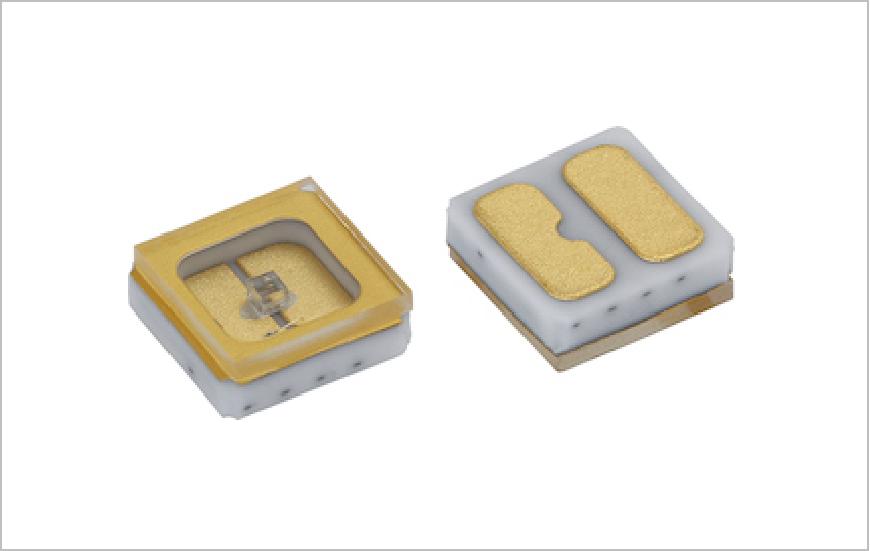

The LED patch light-emitting diode is a combination of N-type semiconductor material and P-type semiconductor material, and each end carries electrons. This arrangement allows current to flow in only one direction. When there is no voltage through the LED chip light-emitting diode, electrons flow from the N-type semiconductor to the P-type semiconductor along the junction between the transition layers, thereby forming a loss zone. In the depletion zone, the semiconductor material will return to its original insulating state-all these "electron holes" will be filled, so there will be no free electrons or an electron vacuum zone and current cannot flow.

The exposed LED luminous characters are metal characters, stainless steel characters, molybdenum characters, and titanium characters. The surface is punched with a single LED waterproof light string. The materials commonly used for the production of exposed LED luminous characters are: acrylic sheet, galvanized sheet, stainless steel, titanium sheet.

First, the method steps of LED exposed LED luminous characters:

1. Tools required for making LED outdoor signs: 30W or 40W electric soldering iron, solder, electric drill, glue gun, screwdriver, etc.

2. Other materials are required for the production of LED outdoor signs: shaped and painted iron, wires, and special power supply for LED signs (DC5V).

3. Drilling: Fix the outsourcing molded iron word to a suitable position, and drill holes (9mm) with an electric drill. The distance is determined by the height of the outdoor brand installation and the production cost. The general LED center distance is: 10—— 30mm, the smaller the i spacing, the higher the brightness and the higher the cost.