After the 0805 SMD LED lamp bead is soldered, the bottom will turn yellow and black, the fluorescent glue will become transparent, the luminous flux will drop seriously, and the color temperature will rise. The proportion of defective products ranges from 1-10%. This is the LED vulcanization phenomenon commonly known in the industry. But no solution was heard.

The principle is: because the 0805 SMD LED lamp bead bracket is silver-plated on the copper substrate (the silver layer will play a role in shining and reflecting light), when the LED is soldered at high temperature, it encounters sulfur or sulfur vapor. And 0805 SMD LED lamp beads, if the air tightness is not particularly good at high temperature, it will cause the silver layer on the bracket to chemically react with sulfur Ag+S=AgSl, forming AgS, depending on the amount of reaction, its color is It is different from yellow light or black light. The serious silver layer has been reacted, and the gold wire is broken, causing the LED lamp bead to open.

Where does the sulfur come from? We took a lot of substances from the problematic customers for chemical element identification, and found that: among the substances submitted for inspection, there are sulfur elements in PCB boards, solder paste, washing water, and other filling glues. However, some manufacturers have no sulfur at all in the materials submitted for inspection. What's the matter? Later, after analysis, in their high-temperature reflow soldering environment, the sulfur content in the air exceeds the standard, and the above-mentioned vulcanization phenomenon will also occur. . This can also explain why the same method does not change when the material is not changed, why it is done in the morning and there is no problem of vulcanization in the afternoon. The customer's use conditions are uncertain, and we cannot predict the customer's welding conditions. And we know that before the LED lamp beads leave the factory, all the LED lamp beads have experienced a high temperature baking of about 80-150 degrees, and there is no problem of vulcanization.

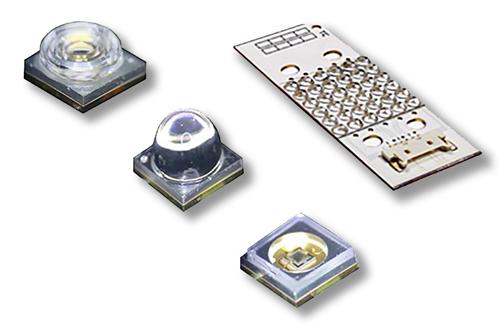

It also means that there is no problem with the LED itself. Therefore, many factories are often at a loss when faced with this problem, but if the customer uses your LED lamp beads, if there is a problem, they can only ask you to pay for it. Can't find the real problem, so many LED lamp bead factories can only choose to lose money or replenish the goods. We analyze this problem in depth from the LED manufacturing part: the material composition of LED lamp beads includes: chip, gold wire, phosphor, glue, bracket. We have done material composition analysis, and the possibility of sulfur in the above-mentioned materials is very small. Sulfur must enter the bracket from the outside world to chemically react with the electroplating layer. The first thing to evaluate is the air tightness of the product, and there are two main reasons for the air tightness problem: one is the LED bracket itself, which is almost the same on the market now. , Although it is not good, it still works. Second, it can only be glue.